Conservation of Water Resources

Quantity of Water Used and Proper Management of Waste Water

The Sapporo Group is continuously striving to reduce water consumption at its production plants. First, we will work to reduce water consumption by 10% from the 2013 level by 2030. We also promote water resource conservation by properly managing the waste water generated.

Sapporo Breweries

Along with the 3Rs of water use in the clean/disinfect processes of beer brewing facilities, efforts are being made toward waste water reduction and proper management of waste water quality, based on the laws and regulations of each region.

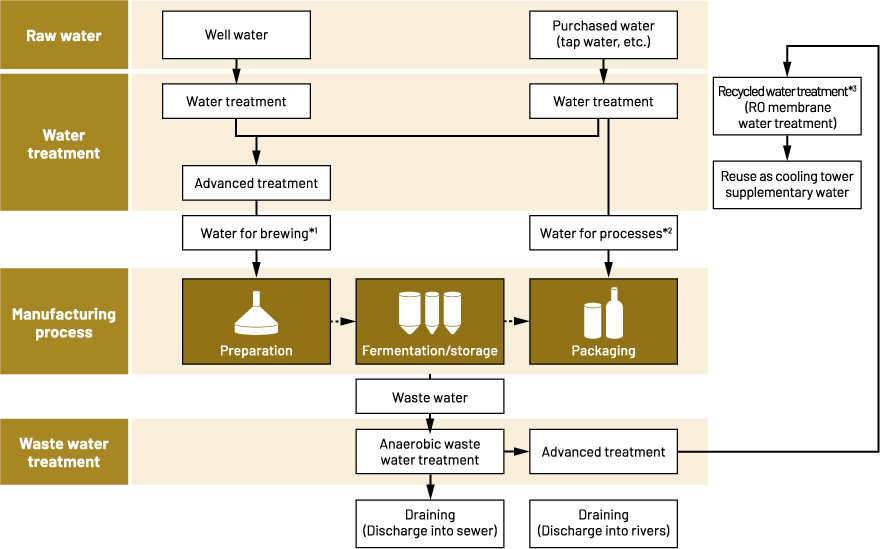

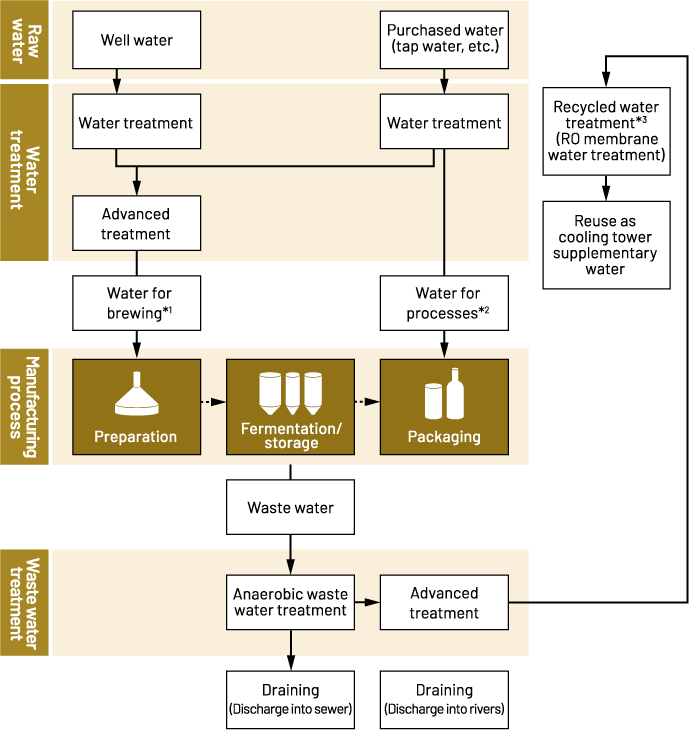

Water Treatment Flow (Conceptual Chart)

*2 Water for processes: Water used for activities such as cleaning equipment.

*3 Recycled water treatment is conducted at a facility in the Shizuoka factory.

POKKA SAPPORO FOOD & BEVERAGE

POKKA SAPPORO FOOD & BEVERAGE strives to manage water consumption appropriately by reviewing the amount and frequency of water used to clean tanks and pipes at manufacturing facilities and the cleaning process.

Status of Water Reuse

Sapporo Breweries

Sapporo Breweries is making efforts to reduce the quantity of water used by reusing waste water from manufacturing (water used in manufacturing processes) for environmental equipment and machine cooling procedures. The reuse ratio is approximately 3 to 5%.

Introducing the waste water reuse system

From 2000, the Sapporo Breweries Shizuoka factory has installed a system that collects and reuses waste water, which used to be discharged into rivers, aiming to efficiently use water resources.

The collected waste water is filtered through a reverse osmosis (RO) membrane* to remove impurities and is reused in areas outside of manufacturing, such as supplementary water for cooling towers and wash water for sludge dehydrators. The waste water collected by this system makes up of approximately 10% of all water used in the Shizuoka factory, resulting in efficient use and conservation of water resources.

*RO (Reverse Osmosis) membrane: A type of membrane filter that only allows water through, and has properties that do not let impurities such as ions and saline pass through.

in the Shizuoka factory

POKKA SAPPORO FOOD & BEVERAGE

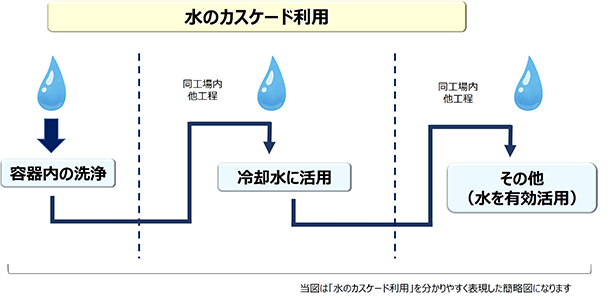

Cascade use of water

POKKA SAPPORO FOOD & BEVERAGE promotes the cascade use of water (a method of effectively utilizing water resources used for cleaning) at its plants.

For example, water used to clean the inside of PET bottles is reused as cooling water for other processes, and other efforts are being made to make effective use of precious water resources.

SAPPORO REAL ESTATE

Recycling waste water and kitchen waste water

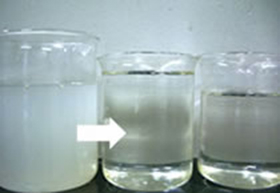

Kitchen waste water and other miscellaneous waste water discharged from the “Yebisu Garden Place” facilities is processed to become recycled water, with decomposition and removal of organic substances using microorganisms through equipment such as the fluidized bed membrane bioreactor. This recycled water is used to water facility greenery or to flush toilets.

Recycled water after treatment (middle),

tap water for comparison (right)

Water Risk Initiatives

Understanding and eliminating water risk

The Sapporo Group is committed to identifying and eliminating water risks because of the large amount of water used at our production sites and the use of agricultural products produced around the world as raw materials.

Water risk at production sites

In order to understand the impact of water risks on business continuity, the Sapporo Group is conducting a survey on its domestic and international production sites by combining the Aqueduct Water Risk Atlas (hereinafter referred to as 'Aqueduct') with actual condition surveys. Aqueduct is a tool published by the World Resources Institute that evaluates global water risks based on latitude and longitude. The risk evaluations for 'Overall water risk' and 'Water Stress' in each site region are as follows.

Overall water risk

| Risk level | 2024 |

|---|---|

| Low | 5 |

| Low - Medium | 23 |

| Medium - High | 0 |

| High | 1 |

| Extremely High | 0 |

* 'Overall water risk' is a comprehensive assessment based on the evaluation of all survey items in Aqueduct. There is no data available for Overall water risk for just one site.

Water Stress

| Risk level | 2024 | 2030 |

|---|---|---|

| Low | 7 | 7 |

| Low - Medium | 7 | 8 |

| Medium - High | 15 | 14 |

| High | 1 | 1 |

| Extremely High | 0 | 0 |

* “Water stress” refers to the ratio of total water withdrawals to the availability of renewable surface and groundwater resources, indicating the level of competition among users.

* The 2030 data represents the projected Water Stress under the Aqueduct 2030 Standard Scenario (a world with stable economic development and steadily increasing global carbon emissions, where the global average temperature rises by 2.6 to 4.8°C compared to 1986.)

The Sapporo Group closely monitors regions classified as “Extremely High” water risk areas, which are regions with high overall water risks, including water shortages, floods, and droughts. As of 2024, there are no production sites classified as 'Extremely High' for either 'Overall water risk' or 'Water Stress.

However, since a part of the region of the Long An plant in Vietnam has been classified as “High” for “Overall water risk,” we have prioritized it as a site for water risk mitigation efforts. We are currently in the process of setting specific goals.

Additionally, one small production site in North America is classified as “High” for “Water stress” both in 2024 and in 2030. However, since this site’s production scale is small and its water usage is minimal, we have determined that its impact on regional water stress is limited. This is the reason why it has not been designated as a priority site for water risk mitigation.

To strengthen risk management at each site, the Sapporo Group maintains continuous communication and information sharing with local governments and water authorities. We are also committed to promoting the efficient use of water at all production sites and will continue to work on reducing environmental impacts.

Going forward, the Sapporo Group will continue to regularly monitor water risks at production sites using tools like Aqueduct. Should any new high-water-risk sites be identified, we will strengthen our measures according to the specific circumstances of each site, aiming for sustainable water management.

Water risk in raw material procurement

Water is an indispensable raw material for the alcoholic beverage and food and beverage businesses, and is also necessary for the growth of agricultural products, so we conduct water risk assessments for agricultural production areas. This time, we surveyed the major regional supplier bases for barley and hops, the main raw materials for our core beer business. As a result, we found that none of the sites were classified as "Extremely High" in terms of overall water risk. The investigation of other raw materials is positioned as an issue for the future. We share our sustainability procurement guidelines with our suppliers and strive to ensure safe and secure procurement through communication.

Activities to Conserve Water

The Sapporo Group supports activities to protect water resources in Miyagi Prefecture’s Shichikashuku Town. Since 2009, Group employees and their families have participated in a variety of activities, such as rice cultivation with farming methods that use fewer agrochemicals. Shichikashuku is the source of the raw material water at Sapporo Breweries’ Sendai factory. Since 2009, Group employees have participated together with the Shichikashuku Genryumai Network in rice-planting and harvesting activities as a way to interact with local communities.

Participation in the Ministry of the Environment Water Project

The Sapporo Group supports the objectives of the Ministry of the Environment's Water Project and is participating in it. We are committed to actively engaging in business activities, environmental initiatives, and awareness-raising efforts that contribute to maintaining or restoring the water cycle.