Reducing of Greenhouse Gas Emissions at Our Sites and Supply Chain

Sapporo Group Greenhouse Gas Reduction Targets

2050

- Aim for net zero greenhouse gas emissions in Scopes 1, 2, and 3.

2030

- Reduce greenhouse gas emissions in Scope 1 and 2 by 42% from the 2022 levels.

- Reduce greenhouse gas emissions in Scope 3 by 25% from the 2022 level.

- Reduce greenhouse gas emissions in FLAG Scope 1 and 3 by 31% from the 2022 levels.

Sapporo Breweries

Sapporo Group Basic Environmental Philosophy

In accordance with our management philosophy “As an intrinsic part of people's lives, Sapporo will contribute to the evolution of creative, enriching and rewarding lifestyles,” the Sapporo Group is committed to ensuring that each and every one of its employees strives to protect the global environment and acts proactively to create a sustainable society throughout the entire lifecycles of the products and services that the Group provides in all of its business fields.

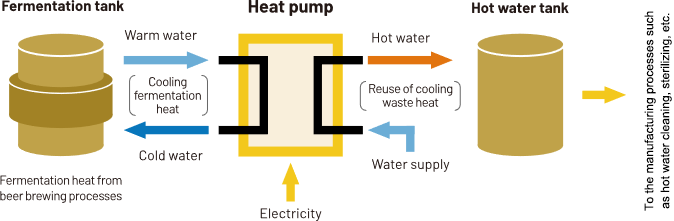

Promotion of global warming prevention by incorporating unused energy sources

Developments in waste heat (unused energy source) collection, which had not been applied up to this point, are progressing and being effectively applied as a heat source for beer brewing processes and other processes to reduce environmental impact (waste water treatment). Energy formerly used for activities such as heating water have been reduced by applying unused energy sources including heat from beer fermentation and waste heat from boiling processes, combustion, equipment, and waste water treatment.

Example of systems installed in factories

(Utilizing heat from beer fermentation)

(Utilizing waste heat from boiling processes)

(Utilizing waste heat from equipment)

(Utilizing waste heat from waste water treatment)

Installation of Solar Power Generation Facilities

Sapporo Breweries has installed solar power generation facilities based on the PPA model* and is promoting the reduction of CO2 emissions through the use of electricity derived from renewable energy sources.

| Jan. 2022 | Gunma factory (Ojima office) | Power generation of 627 MWh/year | CO2 emission reduction amount | approx. 330 tons/year |

|---|---|---|---|---|

| Dec. 2022 | Hokkaido factory | Power generation of 1,539 MWh/year | CO2 emission reduction amount | approx. 840 tons/year |

| July 2023 | Okayama Winery | Power generation of 407 MWh/year | CO2 emission reduction amount | approx. 222 tons/year |

| Mar. 2024 | Value Creation Frontier Research Institute | Power generation of 270 MWh/year | CO2 emission reduction amount | approx. 124 tons/year |

| July 2024 | Kyushu Hita factory | Power generation of 1,276 MWh/year | CO2 emission reduction amount | approx. 612 tons/year |

| July 2024 | Sapporo Vietnam Long An factory | Power generation of 1,043 MWh/year | CO2 emission reduction amount | approx. 706 tons/year |

* A model in which a power producer installs solar power generation equipment on the premises of a company at the cost of the power producer, and supplies the generated electricity to the company

Incorporation and development of new technologies

At Sapporo Breweries, we are working to reduce the amount of fuel and electricity used at our plants by increasing the efficiency of utility facilities* used in the beer production process and reducing operational losses through a review of the volume control system.

* Boilers, refrigerators, compressors, cogeneration systems, heat pumps, etc.

(CO2 refrigerant)

(HFO refrigerant)

Ozone layer protection and suppression of fluorocarbon

Sapporo Breweries is actively moving forward with environmentally-friendly measures in freezing facilities for beer manufacturing processes. With the aim of protecting the ozone layer and curbing global warming, we began switching refrigerants in the refrigeration equipment used in the beer manufacturing process in 2018, and are replacing some of the refrigeration facilities with equipment that uses low-GWP refrigerants or natural refrigerants. Furthermore, equipment inspections are regularly made under the Fluorocarbon Emissions Control Act to ensure legal compliance.

Initiatives to improve transportation efficiency

Since the 2000s, the Sapporo Group has been promoting the joint transportation of goods with companies inside and outside the industry, working to reduce environmental impact through improved vehicle loading rates and reduction in the number of vehicles.

In a recent example, we began joint transportation with NISSIN FOOD PRODUCTS CO., LTD. in March 2022 to carry a combination of beer and instant noodles.

On the Shizuoka-Osaka route, we achieved "round transportation" by carrying mixed products from both companies on the outbound route, and recycled empty containers and pallets on the return route.

This transportation will achieve a 100% loading ratio and reduce CO2 emissions by approximately 10 tons per year compared to the previous method.

Suzuyo Co., Ltd. and six other companies jointly received the highest award, the Minister of Land, Infrastructure, Transport and Tourism Award, at the "FY2022 Green Logistics Partnership Excellent Company Award" for their efforts in collaborative transportation. By setting up relay points in the long-distance transportation section and combining driver switches and ferry transportation to the relay points, they were able to improve the working environment for drivers. In addition, it is expected that the reduction in the number of vehicles used will lead to a reduction in CO2 emissions of approximately 299 tons annually compared to the conventional method.

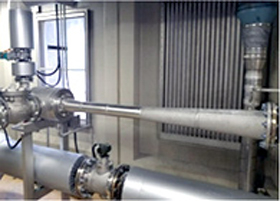

The Sapporo Group has been promoting the reorganization of its distribution bases with an upper limit of 150 km for nationwide deliveries since around 2020.

Starting in April 2024, deliveries to the Hiroshima and Shimane Prefecture area, which were previously shipped from Sapporo Breweries’ Kyushu Hita Brewery, are routed through a new distribution base, the Sapporo Breweries Hiroshima Distribution Center. This alleviates truck drivers' long-distance operation and improves truck turnover rates.

For details, please refer to the news release.

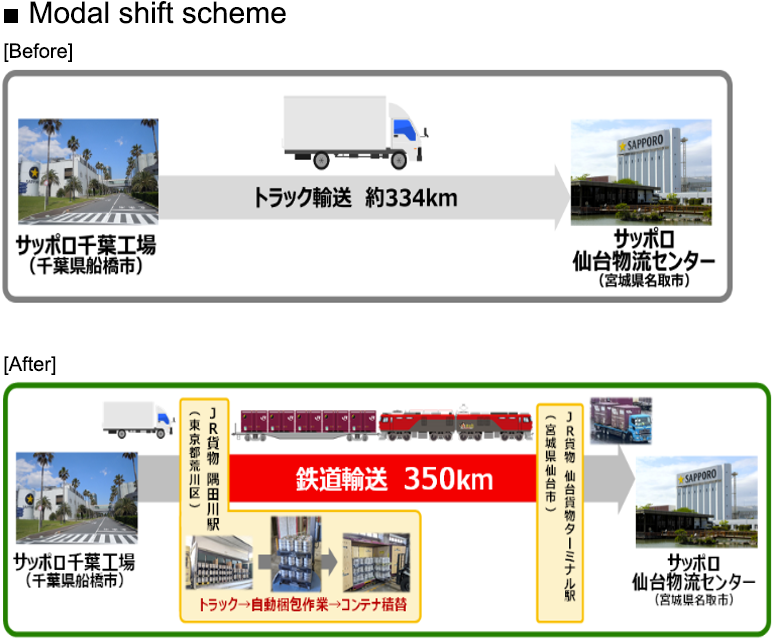

Promotion of modal shift

Sapporo Breweries is working on a modal shift, which is to switch distribution methods from trucks to trains and marine transportation, which results in less CO2 emission. To reduce dependence on truck transportation, the company is promoting a modal shift in medium-distance transportation in addition to long-distance transportation, where such shift has been underway for some time

In February 2024, in cooperation with Japan Freight Railway Company, NIPPON TRANSPORTATION WAREHOUSE Co. Ltd., and Japan Freight Liner Company, part of Sapporo Breweries’ product transportation from Chiba Brewery to Sendai Distribution Center in Sendai Brewery was switched from truck transportation to rail transportation. This is expected to reduce CO2 emissions by approximately 44 tons per year compared to the previous method.

In addition, by using automatic packing machines for packing work to prevent cargo from collapsing during transportation, it is expected to shorten the packing time during shipment by about 30 minutes. This will reduce the workload of workers and the waiting time of truck drivers.

For details, please refer to the news release.

Acquisition of "Green Management Certification"

SAPPORO LOGISTICS SYSTEMS CO., LTD has acquired "Green Management Certification" for its head office and three business sites in Hokkaido, the Tokyo metropolitan area, and Nagoya. The company has also been satisfying certificate renewal criteria every two years since 2008 (most recently passed renewal review in April 2024). SAPPORO LOGISTICS SYSTEMS CO., LTD has been certified and registered for satisfying all items in the Green Management Certification Standards of “Implementing structures/systems for environmental conservation,”“Implementing eco-driving,” “Incorporating low-emission vehicles,” “Vehicle inspection and maintenance,” “Promotion of recycling, proper disposal and disposal control of waste and vehicle scrap,” and “Promotion of environmental conservation in the management department (office).”

Initiatives for Product Environmental Information Disclosure

Products labelling their carbon footprint

*Currently not for sale. Figures are based on a tentative calculation method as of 2009.

In 2004, for the first time in the industry, Sapporo Breweries implemented LCA based on ISO14040 to quantitatively assess the utilized resources and emission of greenhouse gases throughout the entire process of beer manufacturing, from raw materials to manufacturing products and disposal. In 2008, the carbon footprint of “Sapporo Draft Beer Black Label” (CO2 emissions per can) was calculated and displayed at the “Zero Emission House” at the Hokkaido Toyako Summit. In 2009, canned beer with labelling of its carbon footprint was released for sale in Hokkaido for the first time in the world. The calculation was conducted based on "Beer Products" of the Carbon Footprint Product of a Product - Product Category Rule (CFP-PCR) which enabled us to determine the weight, etc. of each process in the product's life cycle. Based on this knowledge, Sapporo Breweries is promoting environmental measures for its products, such as reducing the weight of containers and packaging, as effective measures to reduce greenhouse gas emissions.

| Ingredients procurement | 54% |

|---|---|

| Product manufacturing | 19% |

| Product transportation | 2% |

| Sales | 25% |

** Based on the carbon footprint calculation method

POKKA SAPPORO Food & Beverage

POKKA SAPPORO Food & Beverage's manufacturing plants are steadily engaged in energy-saving activities every year. Nagoya Plant has switched all boilers to once-through boilers and started PPA model solar power generation in November 2023. At Gunma Plant, solar panels were installed on the plant roof and LED lighting was introduced in 2014. Through these efforts, the company is striving for further energy conservation.

Sapporo Lion

Sapporo Lion has been developing environmentally-friendly restaurants in various forms to reduce greenhouse gas emissions.

For “Yebisu Bar,” which has been developing in recent years, and for “Ginza Lion,” which has been growing with new restaurants in various regions, energy-conserving LED lighting has been used for most hall lighting. In existing restaurants as well, lighting has been changed to LED lighting and kitchens have also been transitioning to environmentally-friendly refrigerators and icemakers.

Furthermore, energy and water conservation pamphlets have been distributed to each restaurant and water and utility charges have also been visualized to grasp excess and uneven use in different time slots. Based on information from these activities, energy conservation activities are being implemented during business hours, such as frequently turning switches on and off, configuring proper temperatures for air conditioning and kitchen equipment, along with appropriate operation methods.

SAPPORO REAL ESTATE

Efforts to save energy

At "Ebisu Garden Place," we are committed to promoting energy conservation through various measures. In addition to improving the operation of office building air conditioning systems, we have implemented high-performance Low-E glass windows with excellent heat and insulation properties. We have also gradually transitioned to LED lighting and introduced high-efficiency equipment in line with equipment updates. These efforts are aimed at reducing energy consumption and promoting energy efficiency.

Aiming for zero CO2 emissions

Sapporo Real Estate Development is actively pursuing the transition to renewable energy by using non-fossil fuel certificates for the properties in its portfolio. The electricity sourced by procuring non-fossil fuel certificates is equivalent to 100% renewable energy, resulting in zero CO2 emissions. In addition, we have established a renewable energy roadmap to achieve decarbonization as a company in the medium term, aiming to transition electricity and other energy sources, such as city gas and thermal energy, to renewable sources.