Reinforcing Relationships with Suppliers

Cooperation with Suppliers

Sapporo Breweries / POKKA SAPPORO Food & Beverage

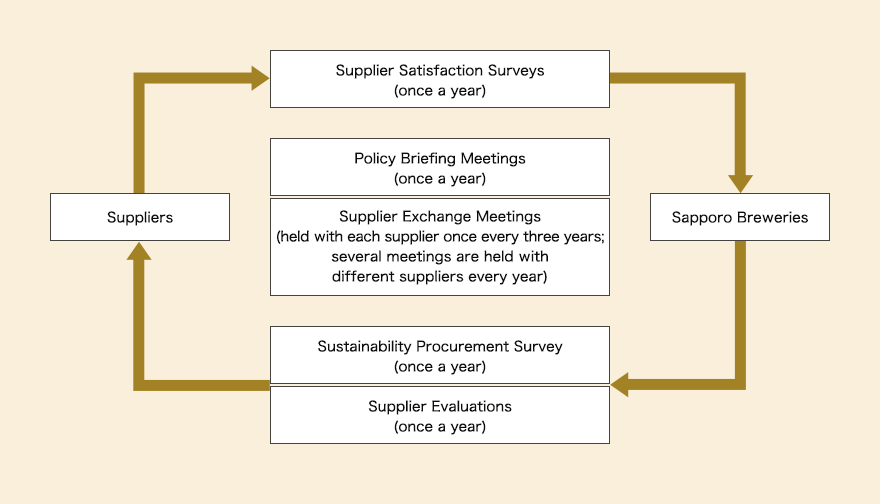

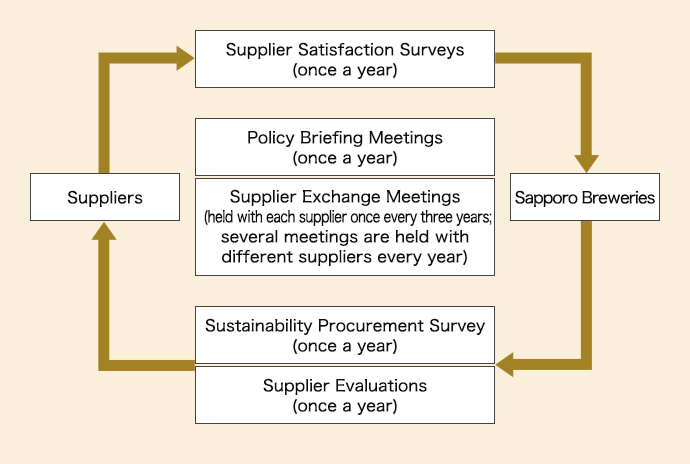

Sapporo Breweries and POKKA SAPPORO hold annual briefing meetings for its suppliers on the subject of the Sapporo Group Procurement Basic Policy. They have also formulated the Sapporo Group Supplier Sustainability Procurement Guidelines to encourage their suppliers to implement concrete sustainability initiatives; through the annual briefing meetings and other occasions, they request their suppliers to deepen the understanding of the guidelines, and work together in promoting them.

Sapporo Breweries and POKKA SAPPORO also endeavor to raise awareness among the group companies of related laws and regulations, such as the Act against Delay in Payment of Subcontract Proceeds, etc., to Subcontractors.

Sapporo Lion

Sapporo Lion offers fair and equitable business opportunities to suppliers, and conducts its procurement activities according to stipulated policies and procedures. Furthermore, the company is committed to reinforce business sales structures focused on “safe, reliable and authentic” raw material selection, product traceability, quality and price, while also continuously verifying manufacturing sites, product specification content and logistics systems and services.

Surveys Conducted on Supplier Satisfaction

Sapporo Breweries / POKKA SAPPORO Food & Beverage

Sapporo Breweries and POKKA SAPPORO conduct Supplier Satisfaction Surveys to confirm and verify whether procurement activities are being implemented according to the Sapporo Group Procurement Basic Policy. Aspects deemed to require particular improvement are swiftly attended to as part of efforts to strengthen relationships with suppliers.

Supplier Sustainability Activity Evaluation and Exchange Meetings

Sapporo Breweries / POKKA SAPPORO Food & Beverage

Sapporo Breweries and POKKA SAPPORO request their suppliers use the Sustainability Procurement Survey to conduct self-evaluations regarding each item of concrete action outlined in the Sapporo Group Supplier Sustainability Procurement Guidelines. The companies also ask their suppliers to sign an agreement on the procurement guidelines in order to increase their understanding and cooperation with the procurement guidelines.

■ Implementation of Sustainability Survey in FY2023

The Sustainability Procurement Survey was sent to 54 suppliers by Sapporo Breweries and 67 suppliers by POKKA SAPPORO.

Of the major suppliers (top 121 suppliers), the percentage of suppliers meeting the sustainability procurement guidelines was 100% based on the survey results.

In addition, the companies have been working to obtain written consent to the Sapporo Group Procurement Basic Policy and the Sapporo Group Supplier Sustainability Procurement Guidelines, and as of December 2023, 100% of the suppliers had submitted their written consent.

Sapporo Breweries also tasks company representatives with carrying out annual evaluations of its suppliers’ initiatives. For packaging and container material suppliers with whom it shares particularly large volumes of business, Sapporo Breweries holds Supplier Exchange Meetings. At these exchange meetings, representatives from Sapporo Breweries purchasing and manufacturing departments visit suppliers and inspect their quality control procedures. These meetings are named “exchange meetings” as they also provide an opportunity for Sapporo Breweries and its suppliers to share knowledge on a wide range of topics, including employee training and sustainability initiatives. Sapporo Breweries holds Supplier Exchange Meetings with each supplier once every three years; several meetings are held with different suppliers every year.

Before commencing transactions with new suppliers, Sapporo Breweries ensures open lines of communication, and carries out factory inspections and quality risk diagnoses.

Cooperation and Communication with Partners

Sapporo Breweries

In addition to the above initiatives, Sapporo Breweries implements the Collaborative Contract Farming System. Under this system, every year before sowing and planting, before harvesting, and after harvesting, we communicate with producers and suppliers of barley and hops to share its thoughts and policies. Where necessary, Sapporo Breweries also inspects the technologies and hygiene management systems being used.

POKKA SAPPORO Food & Beverage

For domestic and international raw material suppliers and manufacturers, visits to production areas and direct opinion exchanges are made when necessary during harvesting and juicing periods, to ascertain quality and stable supplies.

Furthermore, POKKA SAPPORO also has been promoting technical exchange meetings with its material-related suppliers on development of environmentally friendly materials, weight-reducing packaging materials, and to strive for quality enhancement for existing products.

Sapporo Lion

Regular inspections of production areas and processing factories for major food ingredients are made, along with opinion exchanges. Sapporo Lion is also developing new products through its partnerships. For instance, the “Lion Original Sauce” and the original “Genghis Khan (lamb barbecue) Sauce” have been created through its partnership with safe and reliable major partners and are used in major Sapporo Lion restaurants.

SAPPORO REAL ESTATE

At Yebisu Garden Place, staff members of SAPPORO REAL ESTATE and contracted partner companies are stationed at the centers of disaster prevention, facilities, cleaning, waste disposal, parking, greenery management, and delivery, etc., and provide various services.

Regular meetings are held to share information on daily operations, events, etc., and to ensure appropriate communication. In order to maintain a comfortable environment, inspections are conducted on a regular basis, and the results of the inspections are reported and improvements are made together with the companies concerned.

Compliance Training Related to Procurement

Sapporo Lion

Sapporo Lion offers fair and equitable business opportunities to our suppliers and conducts procurement with established policies and procedures. To commit to this, we regularly conduct training on compliance toward the Antimonopoly Law and the Act against Delay in Payment of Subcontract Proceeds, Etc., to Subcontractors (Subcontracting Charges Law). These training activities are not only for executives and product division managers, but are also for all managers at the head office and each store. We will continue to promote regular compliance training through e-learning and in-house educational tools as a company-wide activity, while also requiring product managers to participate in external seminars/lectures once a year.

Our Focus on Raw Materials

Sapporo Breweries

Sapporo Breweries has the belief that “quality materials make quality beer,” and conducts testing and research on processing technologies, material cultivation, barley and hop development (breeding).

Cultivation technologies and various breeds developed through these activities have also supported the current “Collaborative Contract Farming System.”

*For more information about our research efforts and results, click here.

The Collaborative Contract Farming System

Sapporo Breweries applies the “Collaborative Contract Farming System” for hop and malt (barley) procurement, as these are the main ingredients of beer. This system focuses on production areas and cooperates with producers from cultivation to processing procedures. The three main elements of this system are:

1. Well-defined information on barley and hop production area and producers

2. Well-defined information on production methods

3. Communication exchange between the company and producers

Sapporo Breweries conducts in-house training on crop cultivation, processing and breeding for staff called “fieldmen.” These staff members actively communicate with crop producers to create high-quality raw materials. This results not only in delicious beer, but also provides a firm grasp on procurement “where,” “who” and “how” questions. The foundation of “deliciousness” is safety and reliability.

Raw material evaluation conducted by our in-house research division

The research division of Sapporo Breweries conducts raw material evaluation at procurement. The Raw Material Development Laboratory's Raw Material Solution Group and Hokkaido Raw Material Research Group analyze features and components of raw materials such as barley, malt and hops, and also sub-raw materials, to confirm their quality as raw materials for beer and happoshu.

POKKA SAPPORO Food & Beverage

POKKA SAPPORO conducts risk evaluations on new raw materials to be incorporated into products, based on original standards formulated by the company’s rich experience. Food safety and food defense*, recent hot topics, are some perspectives that are incorporated when making selections. Additionally, inspections at local farms and factories are conducted as necessary to make decisions for selection and for guidance.

Furthermore, systematic sanitation and quality factory inspections are conducted for verification and guidance for raw materials already under use, to confirm their quality standard information.

* Food safety is an initiative to ensure food safety by risk evaluation and management of factors that can be assumed hazardous through the manufacturing/supply procedures, to prevent/reduce contamination risks.

* Food defense is an initiative to prevent intentional or human-caused harm to foods.

Sapporo Lion

Sapporo Lion always has “Safe, reliable, and authentic” as its first priority. The food ingredients offered to customers have been procured from origins that ensure the constancy of safety and supply, through close examination of logistic systems, past performances and industry reviews.

Sapporo Lion regularly visits produce regions for ingredients that come directly from farms, and ascertain produce methods, processing procedures and sanitation levels of processing factories before procurement. Furthermore, in the efforts toward further quality enhancement, Sapporo Lion invites producers to its restaurants in the metropolitan area so they can view how their produce is served to customers. Sapporo Lion also makes efforts to improve quality maintenance of products and processed goods excluding farm-direct items, through activities such as regular factory inspections.

- Procurement Basic Policy / Supplier Sustainability Procurement Guidelines

- Respect for Human Rights in the Supply Chain

- Reducing Environmental Impact in the Supply Chain

-

Reinforcing Relationships with Suppliers