Food Safety

The Sapporo Group Quality Assurance System (formulated on November 30, 2011; revised on January 1, 2016)

The Sapporo Group has formulated the “Sapporo Group Quality Assurance System.” By clearly stating its Food Safety Philosophy, Action Guidelines, and Food Safety Program in the System, the Group defines the quality philosophy and actions of each Group company while fostering and establishing a food safety culture. The purpose of this System is to share the Sapporo Group's stance on food safety, which has recently become a top priority, not only with domestic and overseas operating companies, but also with overseas partners in anticipation of accelerated global expansion.

Committing to safe and high-quality products and services

The Sapporo Group carries out thorough compliance, and ensures that it adheres to the requirements of relevant laws and regulations. As a corporate group that handles food, we also guarantee the food safety of our products and services in all of our businesses worldwide.

As a result, we are able to provide our customers with safe and high-quality products and services in a stable and continuous manner.

In addition, in order to provide quality assurance that our customers can trust, it is vital that we prepare preemptively for quality-related issues. If, for any reason, quality-related issues should arise, it is essential that we implement countermeasures and ensure the issues do not reoccur; it is also essential that the countermeasures we implement are applied to other businesses within the Group as appropriate.

In order to fulfill the responsibilities outlined above, Sapporo Group employees will at all times work hard to improve the quality of their products, and continually enhance Group management systems for food quality and food safety.

The Sapporo Group Quality and Food Safety Philosophy

In the Code of Corporate Business Conduct, the Sapporo Group identifies "pursuit of quality and priority of safety in products and services" as a key concern, and seeks to ensure that “prevention-type quality assurance” is a principle shared throughout the Group. In this way, we intend to become a corporation that is trusted by our customers.

These initiatives entail continually improving quality and food safety assurance systems, as well as enhancing the human resources that enable the provision of safe products and services with high added-value. Through these activities, the Sapporo Group intends to provide its customers with satisfactory products and services.

The Sapporo Group Quality Action Guidelines

- We will base our own sense of achievement on the satisfaction and trust of our customers.

- We will respond in a swift and accurate manner to societies and their laws and regulations.

- We will listen carefully to the voices of our customers and, while maintaining objectivity, carry out activities that are visible to our customers.

- We will keep abreast of the latest trends and changes regarding quality and food safety, identify what issues we face, and implement reforms to resolve them.

- We will ensure that Group philosophies and action guidelines are understood by all parties, and improve our teamwork and sense of unity.

The Sapporo Group Food Safety Program

We intend to identify any issues regarding food safety or quality that might result in problems for Sapporo Group products or services, and establish a Food Safety Program that manages these issues. By using a management system based on global standards and by implementing PDCA cycles, we intend to ensure that the Food Safety Program operates appropriately.

Quality Assurance System

The Sapporo Group has set up a Group Quality Assurance Department as an organization to facilitate permeation of a “prevention-type quality assurance” system within and outside of the Group. The Group Quality Assurance Department also monitors whether each operating company has been steadily implementing daily quality assurance activities. We hold regular meetings with quality assurance personnel from each business company within the Sapporo Group to share quality risks and promote measures for their reduction.

Furthermore, the Group Quality Assurance Department and each operating company instructs and monitors procurement partners, manufacturing contractors and domestic/overseas offices under their jurisdiction to improve quality throughout the entire food chain from product planning, development, procurement and manufacturing, to storage and distribution.

Establishment of Global Quality Assurance Systems

Operations for permeation of the “Food Safety Program,” the basics of quality assurance activities, are being made in Group companies overseas as well. Besides having each overseas company comply with local laws and regulations, a quality assurance system based on the “Global Food Safety Initiative (GFSI)* management system benchmark specification” has been constructed according to the products handled and service features of each company.

*GFSI is an organization established in 2000 by the consumer goods-related organization Consumer Goods Forum, with the participation of 70 countries and 650 companies from all over the world. The organization’s primary goal is to reduce food safety risks throughout food supply chains all over the world. As a pillar of this activity, the GFSI certifies existing food safety monitoring standards that satisfy its criteria.

Quality Risk Management

To brace itself for serious quality problems, the Sapporo Group has constructed a Risk Management System which offers swift information sharing of quality risks between operating companies to prevent any issues from happening. Furthermore, regular drills on risk correspondence are conducted at each operating company to reinforce abilities to correspond to risk issues.

Quality Assurance System for Radioactive Substances

Since April 2012, we have been regularly monitoring products and water used as raw materials for radioactive materials and have established a quality assurance system for all group companies.

Sapporo Group's Basic Policy on Animal Testing

The Sapporo Group will not conduct animal testing unless legally required or instructed to do so by the relevant authorities.

Quality Control of Raw Materials

Sapporo Breweries

Traceability is ensured through the “Collaborative Contract Farming System” for malt (barley) and hops procured. In the case of wine, the Japanese wine "Grand Polaire" prints the photos and names of in-house brewing technicians and the producers who cultivated the grapes for raw materials on the label, and is trusted by customers as "wine that shows the face and thoughts of the makers."

Sapporo Lion

At Sapporo Lion, we are committed to ensuring safe and secure procurement of ingredients, and we have integrated our ingredient ordering system with recipe management based on HACCP to provide even safer and more reliable ingredients. We also strive to provide accurate allergen information by linking the allergens used in recipes with recipe data.

POKKA SAPPORO Food & Beverage

POKKA SAPPORO Food & Beverage implements overall quality assurance through its product design, raw ingredients, manufacturing and distribution. The integrated product/raw material information database “Mercrius” has been incorporated to unify product and raw ingredient information, for swift searches of production areas of raw materials used in products, and also to provide information such as that for additives.

Additionally, design reviews* are also implemented for product design, realizing safer product design by evaluating risks from the planning stage.

*Design review: A method that attains one goal before going on to the next step, with evaluation from related divisions (checkpoints for quality) for each process in product creation, such as designing/reviewing/planning, selection of raw materials, selection of factories, prototype manufacturing and mass production.

Group Company Activities

Sapporo Breweries initiatives

Aiming for quality in development, design and manufacturing

Each department related to product development and design has acquired ISO9001 certification, international standards of quality management systems. Furthermore, supporting departments, such as the Quality Assurance Department at the head office, ascertain legal compliance on factors such as product display to support quality assurance in design and development departments. Additionally, seven core manufacturing factories*1 have acquired and implemented the international standard for food safety management systems FSSC22000*2, as part of unceasing efforts to further improve product safety.

View All*1 Seven core manufacturing factories: Hokkaido Brewery, Sendai Brewery, Gunma Plant (Ojima), Chiba Brewery, Shizuoka Brewery, Kyushu-Hita Brewery, Okayama winery

*2 FSSC22000: The acronym for Food Safety System Certification 22000, which is a food safety management system standard targeting food manufacturing organizations. This certification is approved as one food safety certification scheme under the Global Food Safety Initiative (GFSI). It also incorporates HACCP principles.

Factories and headquarters come together for quality assurance

At Sapporo Breweries, the quality assurance, product planning, content and packaging R&D, and manufacturing management departments at the headquarters conduct regular meetings. These related departments work together and share various information, including suggestions and feedback from customers. The information is then reflected in the product development process and the factory manufacturing process.

At the same time, we hold regular meetings at each factory to discuss challenges from the customer's perspective in order to improve product quality, and conduct "Factory Technical Diagnosis" as a cross-functional effort within the technical department.

Diagnosis is conducted by selected staff from various departments. This diagnosis staff identifies issues on-location at other factories and conducts active discussions with factory members. Enhancement of technological levels that support the foundation of “deliciousness” and “quality assurance,” human resource training, and also continued invigoration of organizations can also be anticipated from these initiatives.

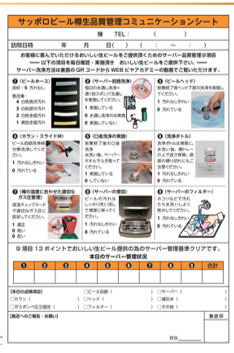

Quality management for kegged products

Sapporo Beer's Draft Beer Quality Centers and Maintenance Centers are located throughout Japan.

In our quality control awareness activities for restaurants that handle Sapporo Keg products, we provide technical advice on draft beer servers, equipment, and containers by using communication sheets and the Web Beer Academy.

Through these activities and equipment maintenance work, the Centers strive for “safe and secure” barrel products to “provide impressive barrel product quality” with restraunts.

Maintenance of draft beer servers

The original barrel draft beer quality management system for Sapporo Breweries, the “SAPPORO SEPARE System” incorporates patented technology and Sapporo know-how to separate barrel draft beer server coolers from beer circuits (tubes in which beer flows, such as beer hoses), which were conventionally inseparable, for better maintainability. The beer circuits are changed regularly and thoroughly cleaned at special maintenance centers. The SEPARE Center’s beer circuit washing machines are responsible for cleaning approximately 90 percent of beer circuits from all over Japan. Developed in-house, these machines control washing temperatures, times, rinsing, and drying in a fully automated manner. It operates to clean 400 to 500 circuits every day. Microorganisms remaining on the washed beer circuits are close to “zero,” making it a “zero reset” for the circuits.

The SEPARE server maintenance center and rows of automatic washing machines

Beer circuits that have been used by restaurants for a certain period of time are exchenged and washed within the company’s maintenance center. The beer circuits themselves are washed at Sapporo’s original automated washing machine, and after disassembling and cleaning the fine components, we use an ultrasonic cleaner thoroughly clean them, making them as good as new. Furthermore, we provide safe and reliable quality by thorough process control, including daily checks of chemical concentration, cleaning time, cleaning temperature, and air leaks throughout the beer circuit.

the evolving “SAPPORO SEPARE System” that sustains overwhelming quality superiority

--Confirmation of waste-suppressing effects at the LCA (Life Cycle Assessment) --

After the introduction of the Sapporo Separe System in 2002, the “SAPPORO SEPARE System” evolved into the “New SEPARE System” by incorporating industry-first components. This attained a “technological revolution” that reduces the amount of impurities within the beer circuits as much as possible. Components include beer hoses manufactured from extremely water-resistant material for more effective cleaning, beer hose joints to reduce the pooling of beer as much as possible, and stainless steel heads. In 2022, the use of beer hoses with improved gas barrier properties will prevent the deterioration of beer more than ever before, and improve the quality of draft beer provided. The "Sapporo SEPARE System" is a sustainable system that ensures both safe and secure quality control and environmental friendliness.

Quality assurance for contract-manufactured products and imported products

In order to maintain and enhance the quality of products whose manufacture is outsourced, Sapporo Breweries technicians conduct inspections at intervals prescribed by designated evaluation criteria. With regard to imported wines, the Wine & Spirits Department and related departments assure quality by analyzing values and checking manufacturing methods for each imported lot, and only then conducting acceptance inspections. Visitations to partner wineries are also conducted when necessary, as part of efforts to strengthen quality management systems.

Logistics quality improvement

Sapporo Breweries was one of the first companies in the industry to improve the quality of its logistics operations (e.g., light shielding and vibration prevention of products during transportation).

Based on the idea that "safety takes precedence over everything else," all employees at Sapporo Group Logistics, which is responsible for the logistics operations of Sapporo Breweries, have established a safety philosophy based on the idea of "safe and secure society" and "improving logistics quality."

Safety philosophy of Sapporo Group Logistics

Safety protects people's smile and creates their future.

We take pride and responsibility as a logistics company, and together with all people involved in the business, we will work tirelessly toward the realization of a safe society.

Based on this safety philosophy, we hold safety rallies for employees of our logistics partners and subcontractors, as well as a forklift driving skill improvement program, to establish safety in the workplace and improve logistics quality in transportation, warehouse operations, and administrative work.

POKKA SAPPORO Food & Beverages initiatives

Participation in and contribution to industry associations

As a food and beverage business company of the Sapporo Group, POKKA SAPPORO Food & Beverages belongs to industry associations*3 that aim to promote initiatives to ensure food safety and quality and to solve social issues. Not only as a company, but also through the various associations to which it belongs, the company contributes to the development of the food industry, verification of the safety of foods and additives, and awareness-raising among consumers, etc.

*3 Japan Soft Drink Association, Japan Fruit Juice Association, the Mineral Water Association of Japan, Japan Soup Association, Japan Food Additives Association, Japan Food Industry Association, etc. (as of December 2024)

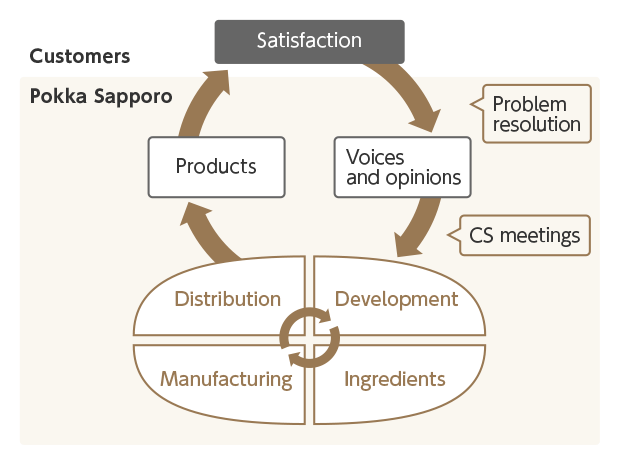

Quality initiatives

POKKA SAPPORO Food & Beverages has constructed a system that evaluates and eliminates risks in each process related to raw materials, product development, manufacturing and distribution, in its mission to be a trusted company that provides products and services that satisfy customers. Furthermore, all customer feedback and opinions are taken seriously as a fundamental policy and are shared within the company to improve quality. Its three factories*4 have acquired FSSC22000 certification, an international standard for food safety management systems, and put it into operation, thereby continually enhancing product safety.

*4 Nagoya Factory (beverages, soup products, etc.), Gunma Factory (beverages), Sendai Factory (soup products)

View AllThe PDCA cycle for customer satisfaction

Sapporo Lion initiatives

Sapporo Lion believes it is its duty and responsibility to offer safe and secure products to customers as a company that provides food. With this, thorough quality and sanitary control is implemented in all aspects from food material procurement to cooking/serving at restaurants, in efforts to ensure the customers’ peace of mind at our restaurants.

Food material quality assurance

Preparation and handling of unforeseen circumstances

In the event issues or concerns stemming from the produce area of food materials, the quality management department of our suppliers will cooperate for swift information disclosure to change the produce areas. We also collect information on a regular basis to ensure the provision of safe food materials.

Continuous initiatives to provide the most delicious draft beer in Japan

As a pioneer company that gave birth to Japan's first beer hall, Sapporo Lion is committed to the slogan "providing Japan's most delicious draft beer" and works on its implementation every day. At the Ginza Lion, in addition to improving the technique of "one-time pour," which is the original way of pouring in a beer hall that allows you to enjoy a fluffy foam and a crisp taste, we are working to provide two types of "Sapporo Black Label": "Perfect Black Label" where you can enjoy creamy foam, and the regular one, to offer a new way of enjoying the same type of beer by comparing the taste by the way it is poured. We also place great emphasis on cleaning and hygiene management of various equipment and glasses used for beer servers. Furthermore, to ensure that customers can always enjoy delicious draft beer at the optimal temperature, we thoroughly manage the temperature in the stores and keep the liquid temperature during beer pouring at 2-3 degrees Celsius.

Sanitation control in stores

Sapporo Lion implements hygiene management that incorporates the concept of HACCP, stores each store's hygiene management records in an electronic system, and promotes visualization of hygiene management. To ensure that our customers can enjoy their meals with peace of mind, Sapporo Lion conducts annual hygiene audits at all of its restaurants nationwide. Additionally, random microorganism testing is conducted on food and equipment to verify quality and ensure safe and secure food is being provided. Any items discovered needing improvement with these sanitation inspections or microorganism testing, will result in requests to the facility to present an improvement report, which will be inspected to see whether improvements have actually been made.

Employee sanitation management training and system establishment

Reinforcing awareness of sanitation management

It is important to heighten the awareness of sanitation management in each employee when implementing thorough sanitation management. For this reason, a “Sanitation Management manual,” a pamphlet that contains basic rules on sanitation management, is distributed to all restaurants. There are also English and Chinese movie versions of the sanitation management manual, to support the many foreign staff members in charge of cooking. We have been attempting to ensure a high level of sanitary awareness throughout the staff, regardless of whether it is part-time, full-time, serving staff or cooking staff, with these pamphlets and movies.

Furthermore, efforts toward individual education are also being made, which include regular fecal examinations, daily health checks, individual e-learning, lectures on sanitation and information related to food sanitation.

Space creation to provide joy

Under the principle of providing the “JOY OF LIVING” through eating and drinking, efforts are made to create a comfortable space with chairs, tables, air conditioning, ventilation, and restaurant designs which eliminate differences in levels for customers in wheelchairs, so that customers can enjoy their meal with peace of mind.